Fuel assessments, Biomass combustion and handling support

Biomass Fuels

Fuel assessment

A proper assessment of a fuel before it is purchased can avoid costly

problems later. The assessment can be tailored to the requirements of the client and targeted to a specific plant.

It can be based on analysis data provided by the client or an analysis of a sample sent to us. The report considers

aspects like: risk for slagging, fouling, bed agglomeration, corrosion, erosion, emissions, self-heating, storage,

milling, etc.

A detailed understanding of the fuel supply to any project is vital, whether this is at the design

stage or as part of an operational fuel supply. BioC can assist with the preparation of a fuel specification and

QA requirements.

Solid biomass fuels are physically very diverse but they tend to be dusty if dry and self-heat

if wet. They are often of extremely low bulk density which makes transport costly. This can be improved by

pelletising or briquetting but this adds to the production cost and if any additives are required in this process,

this can have implications for the combustion, and increase the risk for bed agglomeration in a fluidised bed, etc.

BioC can assess the options for storage, handling and combustion related risks.

Will the biomass be processed in an existing milling plant as in many co-firing installations or in a purpose built

facility? Different types of biomass materials behave very differently in different types of mills. They also need

different amounts of preparation depending on combustion technology. Wood chips can be burned without milling in a

fluidised bed boiler whilst they need to be milled to a fine powder to be fired in the flame from a pf burner.

Fuel Safety

Biomass fuels tend to be more prone to self-heating than coal if moist.

The mechanisms for-self heating are different so the mitigations need to be different. There are many examples of

biomass fires that illustrate the importance of this.

Biomass fuels can also be very dusty, with wood pellets as a prime example of this. Dust clouds can ignite more easily

than typical clouds of coal dust due to a lower ignition energy (MIE) for many biomass materials. This dust is both a

safety hazard due to the risk for explosion, and a health risk, particularly with hard wood dust that is classifieds

as carcinogenic.

There has been many incidents connected to:

- Dust explosions and fires

- Self-heating and spontaneous ignition (an internet search will give many examples of this)

- Release of hazardous gases, like Carbon monoxide and Methane from biomass stored in closed areas (this has led to fatalities when people have entered the area without checking oxygen and CO-levels)

All these causes are well known and understood and it is also known

how to prevent them. Despite this, people still lose their lives due to this type of accidents.

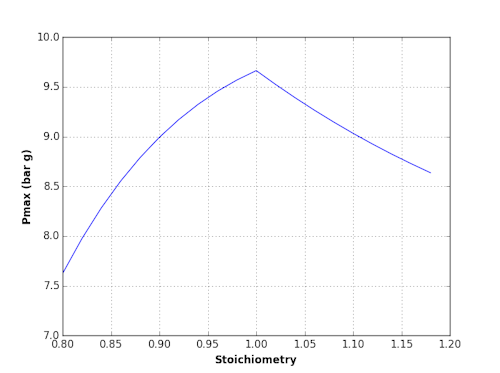

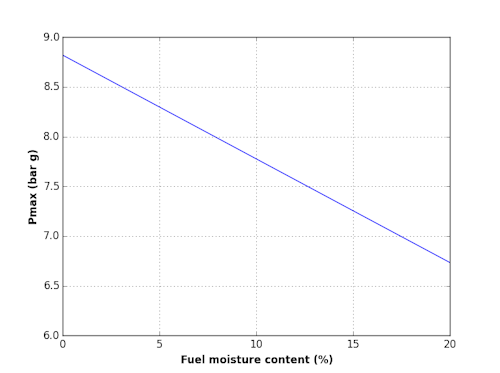

BioC has recently developed software capable of calculating the maximum explosion pressure (Pmax) from the Proximate

and Ultimate analysis of a fuel. This allows a more thorough analysis of the impact of factors like moisture content

of the fuel and the temperature of the reactants before the explosion that is not economically feasible using the

expensive experimental method. The Pmax for an explosion in a reactor held at an elevated temperature is lower than

if it was at room temperature. A lower temperature gives a higher Pmax so an explosion taking place in the winter

at -5 degrees C will be more severe than one taking place at +25 degrees C all other factors identical. An understanding

of this relationship is useful in reactor design and for developing mitigation strategies. The theoretically highest

pressure that can be achieved during an explosion (in air) is for an absolutely dry fuel perfectly mixed in stoichiometric

proportions with air. The software can show how much higher this pressure is compared to the experimentally determined

that will hold some moisture. See the diagram below for an example of the maximum pressure as a function of the

stoichiometry of the fuel/air mix and of the moisture content of the fuel.

Co-firing feasibility

The assessment of co-firing potential at coal fired power stations is a speciality as well as advice on fuel diet for

a co-firing station.

Many factors are important to take into consideration in a decision to introduce co-firing. Some (but not all) are:

Commercial viability, availability of the intended biomass fuel, transport, storage, conveying, processing (milling),

combustion, emissions, impact on flue gas flow and fan capacity and SAFETY both process safety and occupational safety.

Conversion of coal fired plant to 100% biomass

BioC has been heavily involved in a number of on-going conversions of coal fired power stations in the UK to 100% biomass firing in recent years, including what at the time of conversion was beleived to be the largest 100% biomass fired power station in the world. This involvement includes materials handling, milling and combustion as well as fuel and safety assessments. This work has involved almost all issues discussed on this web site.

Milling of biomass fuels

Milling is a crucial part of the preparation process and has to be done to sufficient fineness to allow the fuel

particles to burn out before leaving the combustion chamber at the same time as the traditional fineness used in

coal mills is unecessarily fine and both limit the throughput and results in excessive power consumption in the

milling plant when biomass is being processed. Biomass fuels are mechanically very different to coal and behave

differently in the mill and classifier. Co-milling of coal and biomass in an unmodified coal mill can be successful

up to a certain level that varies between types of mill and biomass fuel. Many plants try to use their existing coal

mills for 100% biomass, which is possible and has been done successfully at several power stations. Wood pellets,

in particular, are suited for this, but the mill and classifier will need some modifications to work well. This is

an area where BioC has experience from numerous projects.

Fire and explosion safety in the mill needs reviewing to ensure that the differences in properties between coal and

biomass are reflected in the updated safety procedures.

Safety

Safety measures for handling and storing of different biomass fuels needs to be completely different to those used in

coal fired plants due to the different nature of the biomass fuels. The energy required to ignite a dust cloud is typically

an order of magnitude lower for many biomass fuels than typical hard coals which means that a spark that has too low energy

to ignite a coal dust cloud can cause an explosion if the dust cloud is generated from biomass fuels. Self-heating is another

potential safety hazard and takes place through different mechanisms compared to coal. Biomass self-heats through organic

processes and can be extremely fast in moist fuels. An initial fast temperature increase will often take place and reach a

plateau, where the temperature level is determined by the temperature tolerance of the micro-organisms in question. This

plateau will be followed by a second phase with increasing temperature caused by micro-organisms with higher temperature

tolerance. Monitoring procedures and trigger levels for mitigating measures to avoid the self-heating leading to a

spontaneous fire need to take this characteristic into account.

An internet search reveals numerous examples of fires and explosions in plant handling biomass materials. Many of them completely

avoidable if correct mitigations and safety measures had been taken, with suitable procedures in place (and followed).

BioC has been providing assessment and design of all aspects of preparation, transporting and burning the biomass fuels both for

full conversion and co-firing at coal fired plants in numerous countries around the world.