Fuel assessments, Biomass combustion and handling support

Computer simulations

Computer simulations can range from simple spreadsheet calculations to massive simulations using commercial CFD

software. BioC is of the opinion that there is a place for both and particularly the middle ground with models

that are more sophisticated than what is practical to do in a spreadsheet, but without the complexity that makes it

difficult to understand all the the assumptions that have been made in the submodels used in the simulation.

BioC has experience of some of the most used CFD codes like Fluent, Start CD, Phoenics, but also from using and

developing simulation software in Fortran, Python, C, Pascal, Delphi etc. The work today is focussed on Python but

legacy codes in Fortran are frequently used. And, as mentioned, there is a place for spreadsheet models as well,

and they are frequently used at BioC. But there is a point where a spreadsheet becomes very difficult to debug and

maintain. That is the point where it makes sense to move to a language such as Python or Fortran.

Computer simulation models developed by BioC

BioC has been involved in the development of many computer simulation models. Some examples are given below:

- Maximum explosion pressure (Pmax) model (Sample output)

- Particle combustion model

- Combustion flue gas model

- Heat balance for coal mill (Sample output)

- Fuel assessment software

- Transient heat transfer in a power station wall

- Model of isothermal compressor

Explosion calculations

The maximum pressure that can be generated in an explosion (Pmax) is a very important safety factor for equipment handling fuel

in an enclosed environment, like mills, classifiers and pf-pipes.

BioC ltd has developed software that can calculate the Pmax from the chemical composition of the fuel and its calorific value.

This allows the simulation of explosion pressures generated in different situations.

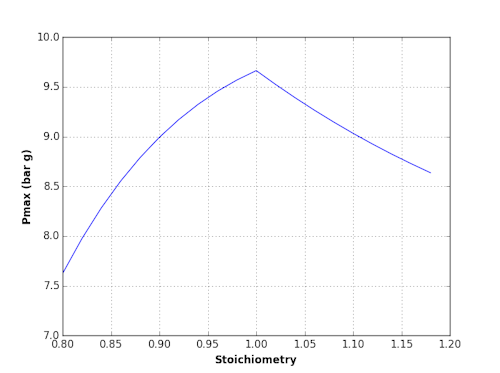

The plot below shows the impact of

stoichiometry (i.e. fuel/air ratio) on the explosion pressure for one particular fuel. So an experimental determination on a

fuel sample with 1-2% moisture will under estimate the potential explosion pressure caused by completely dry fuel and a room

temperature determination will seriously overestimate the pressure that can be caused by an explosion in a vessel that is always

at an elevated temperature when there is a risk for an explosion to occur.

An example report from this type of simulation can be found here. The calculated Pmax for this

particular biofuel was 9.66 bar g and the experimental test gave 9.6 bar g.

Maximum explosion pressure for a mixture of combustible dust with air in varying proportions.

Combustion calculations

Particle combustion

The impact of particle size and shape on the burnout time of the fuel particle is significant. It is also essential to match

this to the residence time in the combustion chamber. BioC has a model for the calculation of drying and devolatilisation

time depending on the size and shape of a fuel particle. The impact of shape is

illustrated in the diagram below showing a spherical particle and a particle with non-spherical shape and the same mass,

but with twice the surface area. See the section on microscopy for more information on determination of particle shape.

Combustion gases and flame temperature

The volume flow and composition of flue gases vary along the gas path in a boiler due to changes in temperature and oxygen

concentration (caused by air ingress). The increased gas velocity resulting from air ingress will result in increased erosion

as well as reduced overall efficiency and will also affect the performance of dust filters, particularly electrostatic

precipitators (ESP). If the gas flow increases beyond the capacity of the fans (due to excessive air ingress or a change in fuel),

the consequence will be a forced derate of the unit output.

Replacing some or all of the coal with biomass has consequences for both the flow of gases that are generated during the combustion

and the temperature. Biomass fuels generally have a lower calorific value so to generate at the same level, more fuel is needed and

more gases will be generated. The increase in required fuel flow will affect mill capacity.

All this has implications for transport velocities and risk for erosion. Higher gas flow will also result in higher velocities in the convective

section of the boiler and will affect the heat transfer.

Coal mill model

When a coal mill is converted to biomass the temperature of the mill inlet temperature need to be restricted due to the lower ignition

temperature of most biomass materials compared to coal whilst the mill outlet temperature will still need to be kept at a level

above the dew point and high enough to give good flame stability. This will limit the amount of moisture in the fuel before the outlet temperature

drops too low. The BioC mill model can analyse the mass and heat balance of the mill for a specific fuel and produces a report like this

and a Sankey diagram of the heat balance as below.

Bespoke simulations

BioC ltd can develop bespoke simulation models (in FORTRAN or Python) for many heat or combustion related problems. Some examples of simulation models developed in the past are:

- Dynamic model of temperature profile in a power station chimney to determine the maximum duration of a flue gas temperature excursion before the structural integrity of the chimney will be compromised. This is when the temperature excursion reaches a temperature above the maximum allowed for the glue holding lining bricks in place.

- Dynamic calculation of the gas pressure in the cylinder of a compressor with a water spray applied inside the cylinder for increased efficiency.

- Impact of windbox shape on the difference in trajectory of the air jets from nozzles placed along the windbox.